SlagTracker

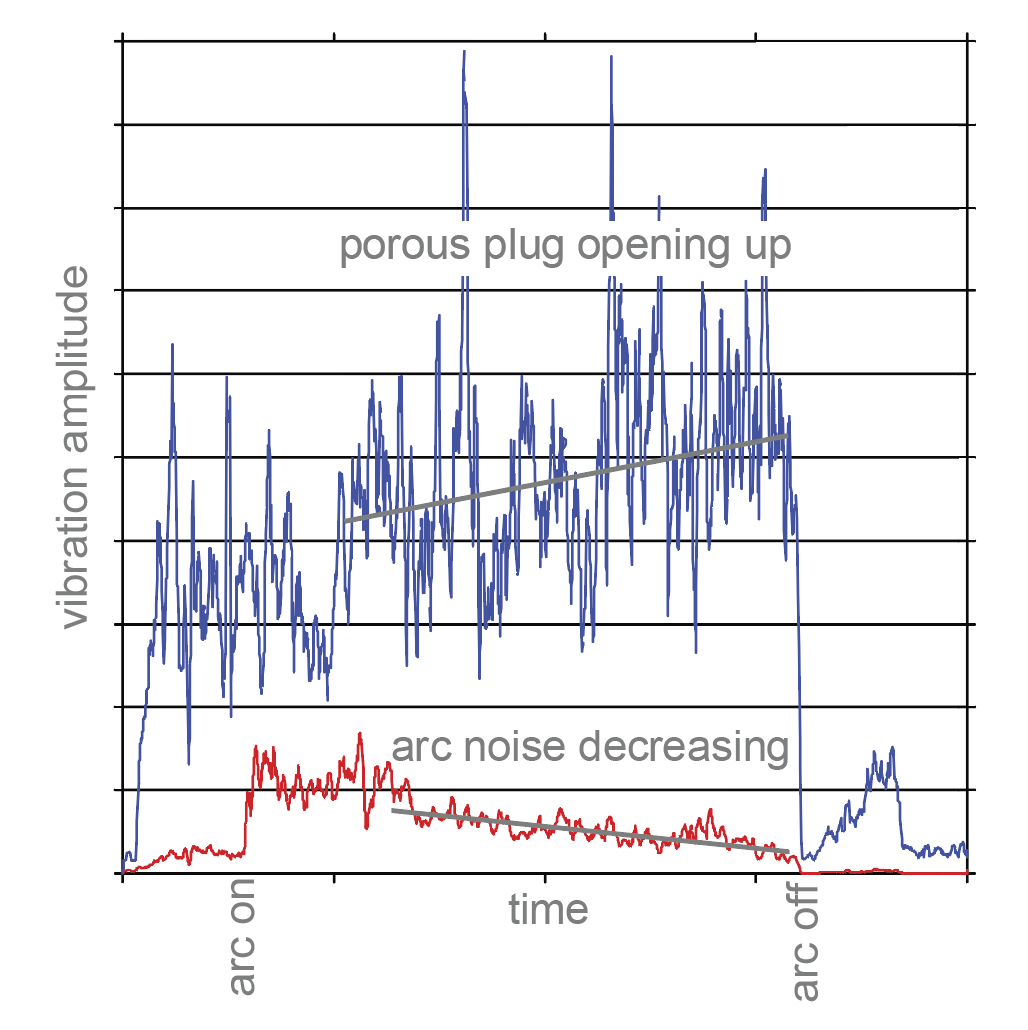

Installed in over 50 steel plants globally, Opta’s SlagTracker System is an advanced solution for slag detection, offering consistent control. Recognizing the initial incidence of slag entrainment in the steel stream, the system can minimize slag carryover or maximize steel yield. A specialized Tundish camera provides a redundant alarm and valuable insights for monitoring flux cover. The system features grade-specific sensitivity, a custom HMI, and optional shroud alignment, ensuring flexibility and optimal ladle shut-off times. Self-diagnostics, plant data flexibility, and rapid commissioning support ease of implementation. With advanced image analysis, the SlagTracker System stands as a reliable and comprehensive tool for operators.